In the dynamic world of logistics, efficient fleet management is critical for keeping operations smooth, timely, and cost-effective. One of the biggest challenges in fleet management is preventing unexpected breakdowns that can lead to costly delays and repairs. Enter AI-driven predictive maintenance — a technology that can help logistics companies foresee potential issues before they happen, minimizing downtime and reducing maintenance costs. In this blog, we dive into how AI-based predictive maintenance works, explore a Python implementation with a visualization example and discuss the benefits of this powerful tool. By harnessing the insights from predictive maintenance, logistics managers can plan more proactively and transform fleet management into a forward-thinking strategy.

Predictive Maintenance with AI: Python Code Sample and Visualization

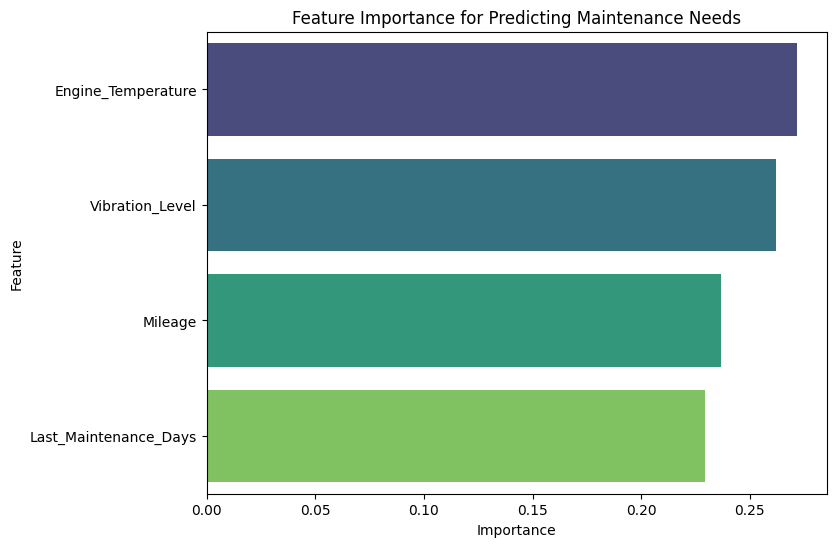

Predictive maintenance uses data analytics, machine learning, and AI to forecast maintenance needs based on various factors such as engine temperature, mileage, vibration levels, and historical maintenance data. This implementation example demonstrates a simple predictive maintenance model using Python and a dummy dataset.

Prerequisites: To replicate this setup, you’ll need Python installed with the following libraries:

Pros of AI-Based Predictive Maintenance in Logistics

- Reduced Downtime: AI algorithms predict maintenance needs before breakdowns occur, minimizing unplanned downtime.

- Cost Savings: By addressing potential issues early, companies can avoid high repair costs.

- Enhanced Safety: Proactively maintaining vehicles reduces the risk of accidents caused by mechanical failure.

- Improved Asset Lifespan: Predictive maintenance extends vehicle lifespans by ensuring timely intervention.

- Operational Efficiency: Reduced breakdowns translate to smoother operations and better customer service.

How Nivalabs Can Assist in the Implementation

At Nivalabs, we specialize in building AI-driven solutions tailored to industry needs. Our team of experienced data scientists and software engineers can help your organization implement predictive maintenance using AI. Whether it’s model selection, data collection strategies, or deployment, Nivalabs provides end-to-end support to ensure your predictive maintenance system is accurate, scalable, and fully integrated with your existing systems.

Our expertise includes:

- Custom Model Development: We can design predictive models customized to your fleet’s specific requirements.

- Data Integration: We facilitate seamless data integration across multiple sources, such as IoT sensors, maintenance records, and vehicle telematics.

- Real-Time Monitoring: Nivalabs enables real-time monitoring solutions that give you up-to-date insights into vehicle health.

- Continuous Optimization: We offer ongoing support to refine models as your data evolves, ensuring sustained accuracy and reliability.

References

- How Predictive Maintenance is Revolutionizing Fleet Management

- Machine Learning for Predictive Maintenance: A Comprehensive Guide

- Implementing AI in Logistics: Benefits and Best Practices

Conclusion

Predictive maintenance with AI is a game-changer in the logistics domain. By integrating machine learning and AI-based prediction models, logistics companies can proactively address maintenance needs, ultimately reducing costs, enhancing operational efficiency, and improving fleet safety. With the right expertise, AI in predictive maintenance enables logistics firms to look ahead and maintain their fleets with precision. As the industry grows, solutions like these will be essential for competitive advantage and operational resilience.